Arc Welding

The process begins with a device that gives off an electric current.

This device can differ greatly from process to process yet it always enables electric

current to move through materials that without the device, would be considered non-conductive.

It is called ‘arc welding’ because an electrical current is created between the welding device and

the materials to be welded which at times gives an arch like appearance. The first basic form of

arc welding was invented in the year 1802.

This device can differ greatly from process to process yet it always enables electric

current to move through materials that without the device, would be considered non-conductive.

It is called ‘arc welding’ because an electrical current is created between the welding device and

the materials to be welded which at times gives an arch like appearance. The first basic form of

arc welding was invented in the year 1802.

Electroslag Welding

Electroslag is a generally fast welding process used to join large materials

such as thick steel plates. These plates or materials are usually arranged in a vertical position, as

the Electroslag weld is designed to weld at this angle without causing distortion to the welder. The name

‘Electroslag’ was derived from the use of water filled copper areas within the device, which were included

and designed solely to prevent melted ‘slag’ from pouring into other areas as it liquefied.

such as thick steel plates. These plates or materials are usually arranged in a vertical position, as

the Electroslag weld is designed to weld at this angle without causing distortion to the welder. The name

‘Electroslag’ was derived from the use of water filled copper areas within the device, which were included

and designed solely to prevent melted ‘slag’ from pouring into other areas as it liquefied.

Flux-Cored Welding

Flux-cored welding was created and put into use in the early years of the 1950’s.

Its purpose was to give another option to the popular use of ‘stick welding’. The Flux-Cored process is mostly

used for projects that require fast speed as it is an automatic form of welding. Many construction workers use

this process on the job because of the speed and the ability to use flux-cored welding in multiple situations

on various materials.

Its purpose was to give another option to the popular use of ‘stick welding’. The Flux-Cored process is mostly

used for projects that require fast speed as it is an automatic form of welding. Many construction workers use

this process on the job because of the speed and the ability to use flux-cored welding in multiple situations

on various materials.

Gas Tungsten

Arc Welding is considered to be one of the most difficult and time consuming of welding

processes used today (along with Plasma Arc Welding). This is because it requires a great amount of focus

and skill due to the small area of space between the ’arc’ of the flame and the material being welded.

Usually, small strips of metal that do not contain much iron are welded with this process. Though it is difficult,

it produces extremely strong high quality welds when done correctly. Welders manufacturing bicycles and aircraft,

both commercial and military, use Gas Tungsten-Arc Welding often while many other welders will never come across this

process.

processes used today (along with Plasma Arc Welding). This is because it requires a great amount of focus

and skill due to the small area of space between the ’arc’ of the flame and the material being welded.

Usually, small strips of metal that do not contain much iron are welded with this process. Though it is difficult,

it produces extremely strong high quality welds when done correctly. Welders manufacturing bicycles and aircraft,

both commercial and military, use Gas Tungsten-Arc Welding often while many other welders will never come across this

process.

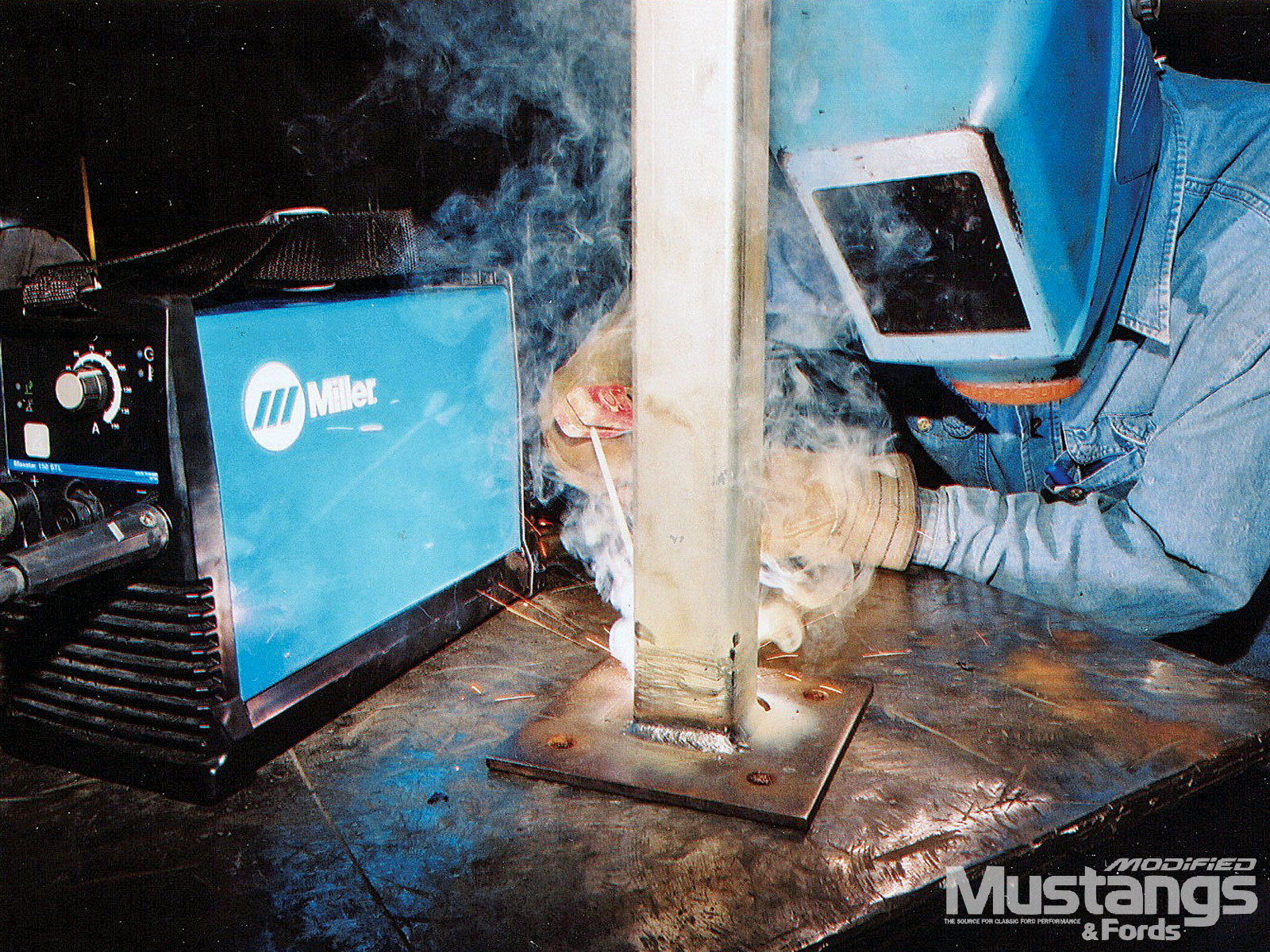

MIG (Metal Inert Gas) Welding

Metal Inert Gas Welding is a process of welding that uses a gas to shield the weld metal.

The gas keeps the metal being welded from being effected from natural elements in the environment, such as oxygen. This allows

the welder to operate at a continuous rate, making the process fairly quick. Operation of the equipment does not require an

extreme level of skill by welders, however, the equipment used in MIG Welding can only be used indoors due to the gas involved

in the welding process.

The gas keeps the metal being welded from being effected from natural elements in the environment, such as oxygen. This allows

the welder to operate at a continuous rate, making the process fairly quick. Operation of the equipment does not require an

extreme level of skill by welders, however, the equipment used in MIG Welding can only be used indoors due to the gas involved

in the welding process.

Plasma Arc Welding

Plasma Welding is very much like that of Gas Tungsten-Arc Welding (GTAW). The two processes are often

compared because they basically work in the same fashion, only using a different type of torch. This method was developed in

1954, though even today, it is still being improved upon. Plasma Welding also requires more concentration than GTAW because of

the smaller arc and precision of the weld. In Plasma Welding, the electrical current is passed through an extremely small

nozzle which passes through the protective gases, enabling extreme accuracy when welding small areas. Plasma Welding can

heat metals to very extreme temperatures which can result in deeper welds.

compared because they basically work in the same fashion, only using a different type of torch. This method was developed in

1954, though even today, it is still being improved upon. Plasma Welding also requires more concentration than GTAW because of

the smaller arc and precision of the weld. In Plasma Welding, the electrical current is passed through an extremely small

nozzle which passes through the protective gases, enabling extreme accuracy when welding small areas. Plasma Welding can

heat metals to very extreme temperatures which can result in deeper welds.

Shielded-Metal Arc Welding

This process is known to be the most popular and widely used processes in welding today.

The first form of SMAW was created in 1938 but the process and equipment continues to undergo upgrades. It is a manual welding

process that is very simple and inexpensive to operate. The results often are not as ‘neat’ as other methods and molten splatter

is a common occurrence. Stick welding is mostly used by construction welders working on steel structures and other industries

that require welding but do not have large budgets.

The first form of SMAW was created in 1938 but the process and equipment continues to undergo upgrades. It is a manual welding

process that is very simple and inexpensive to operate. The results often are not as ‘neat’ as other methods and molten splatter

is a common occurrence. Stick welding is mostly used by construction welders working on steel structures and other industries

that require welding but do not have large budgets.

Submerged Arc Welding

The Submerged Arc Welding process can only be used properly on materials containing high iron contents,

such as stainless steel. The device used in this process can be automatic or semi-automatic making it a fairly fast welding process.

While it is a fast process, the electrical arc must constantly be covered by ‘flux’ in order to protect the metal from the atmosphere

during the welding process. This cover also prevents any welding spatter which makes it safer for welders than some of the other forms

of welding.

such as stainless steel. The device used in this process can be automatic or semi-automatic making it a fairly fast welding process.

While it is a fast process, the electrical arc must constantly be covered by ‘flux’ in order to protect the metal from the atmosphere

during the welding process. This cover also prevents any welding spatter which makes it safer for welders than some of the other forms

of welding.

TIG (Tungsten Inert Gas) Welding

Tungsten Inert Gas welding is much like the process of Metal Inert Gas (MIG) welding. The main

difference between these two forms of welding is that TIG uses a tungsten current form, while MIG uses a metal electrode. Because TIG

uses tungsten, it requires an additional filler placed inside the welding device as tungsten does not melt in the welding process.

Tungsten is unique as it can be heated to a higher temperature before melting than all other metals. Tungsten Inert Gas Welding is

usually used in industries that work with stainless steel.

difference between these two forms of welding is that TIG uses a tungsten current form, while MIG uses a metal electrode. Because TIG

uses tungsten, it requires an additional filler placed inside the welding device as tungsten does not melt in the welding process.

Tungsten is unique as it can be heated to a higher temperature before melting than all other metals. Tungsten Inert Gas Welding is

usually used in industries that work with stainless steel.